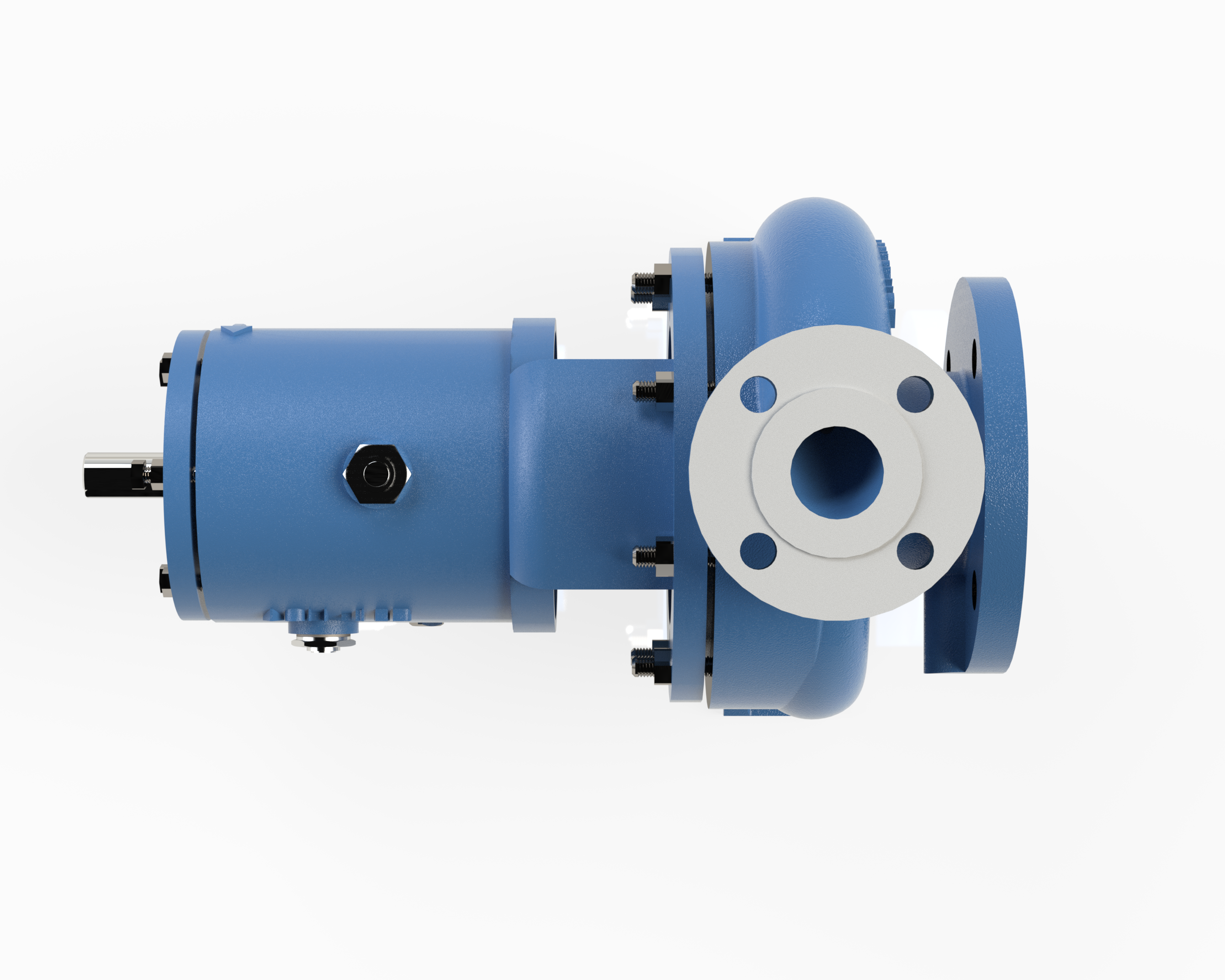

ACH 4

ACH 1

ACH 3

ACH 05

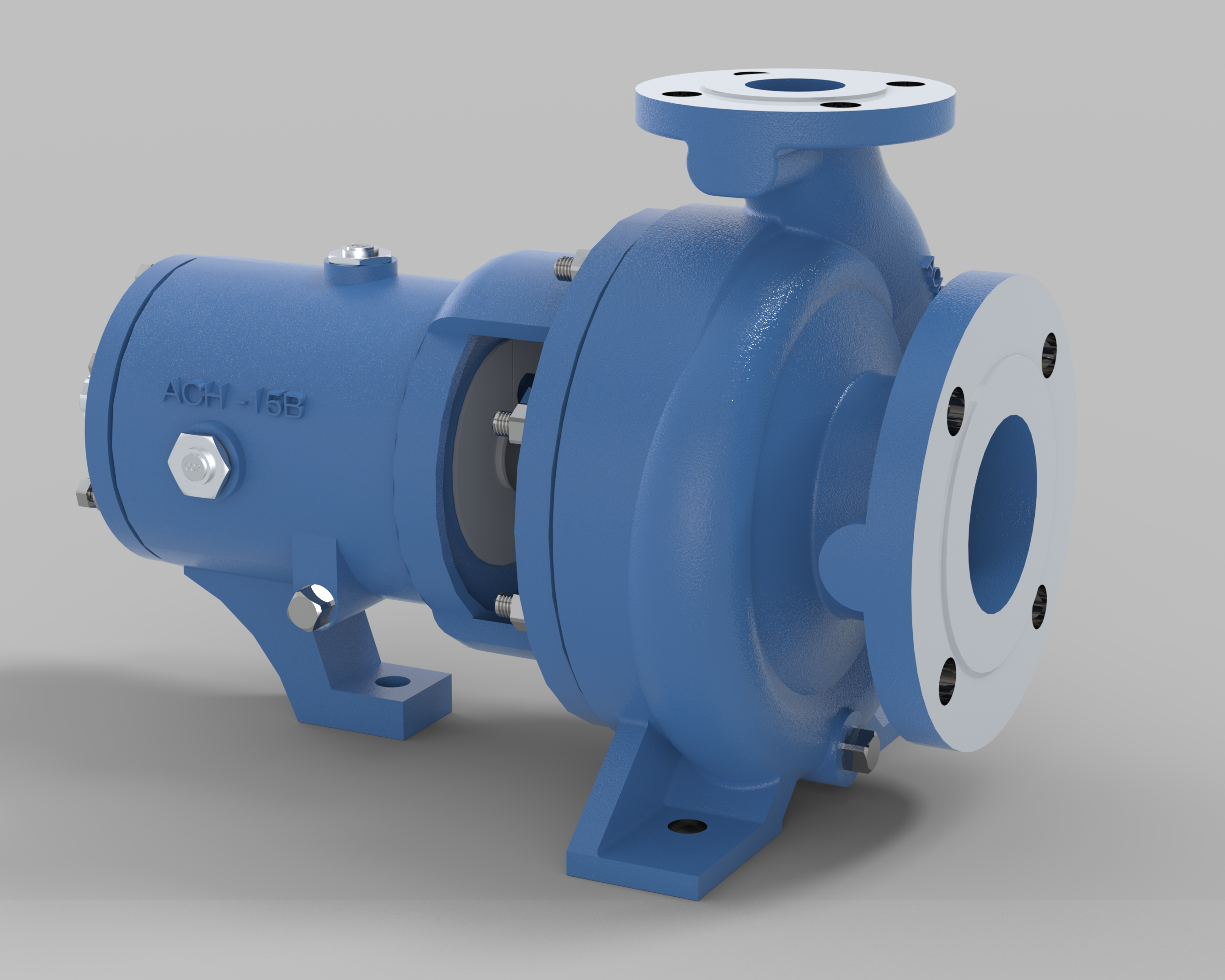

KEERTHI – ACH -Series Chemical Process Pumps, Rugged process pump is ANSI / ASME B73.1 compliance and operates even in the toughest industrial and chemical applications. Offered with exclusive designs, these are apt for transferring highly aggressive, abrasive as well as viscous products.

| Pump Delivery Size D | DN 25 to DN 100 |

| Head H | Up to 180 mtrs (590feet) |

| Capacity Q | Up to 600 m³/hr |

| Max.Operating (Temp) | 200 °C |

| Max.Working Pressure | 24 bar |

| Speed N | 960/1450/2900 rpm at 50 Hz |

| Speed N | 1200/1750/3500 rpm at 60 Hz |

Acids, Brine, Fertilizer, Steel & mining, Pulp & paper, Chemicals, Power

generation

Slurry, Solvents, Textile, breweries, Jet dyeing,

Grain processing, Sugar, Distilleries, Refineries, Food processing,

Pharmaceuticals, Steel,

Water treatment, oil & gas, Petrochemicals, Automotive, Oil Extraction and Waste,

Cellulose, hypo, spent wash, starch handling, green liquor, black liquor

Caustic slurry lime mud slurry, extraction, China clay, Effluent Treatment

Plants

Organic and Inorganic Liquids Refineries

| Specifications | Range |

|---|---|

| Pump Delivery Size D | DN 25 to DN 100 |

| Head H | Up to 180 mtrs (590feet) |

| Capacity Q | Up to 600 m³/hr |

| Max.Working Pressure | 24 bar |

| Max.Operating Temperature | 200 °C |

| Speed N | 960/1450/2900 rpm at 50 Hz |

| Speed N | 1200/1750/3500 rpm at 60 Hz |

ACH 20/160

ACH 25/130

ACH 25/160

ACH 25/180

ACH 25/200

ACH 25/230

ACH 40/130

ACH 40/160

ACH 40/180

ACH 40/200

ACH 40/230

ACH 40/260

ACH 40/300

ACH 50/180

ACH 50/230

ACH 50/260

ACH 50/300

ACH 80/230

ACH 80/260

ACH 80/300

ACH 80/400

ACH 100/230

ACH 100/260

ACH 100/300

ACH 100/400

Back pull-out design

Conform to ANSI B73.1dimensions

High efficiency hydraulic design

Heavy duty shaft, sleeve and bearings

Low NPSH, lesser Noise and maintenance free

Single and double mechanical seal

High standardization, easy installation and robust construction equate to

reduced maintenance and operating costs

Maximized reliability thanks to improved shaft sealing Design and heavy-duty bearing unit

Easy maintenance through the Back-Pull-Out principle

Single unbalanced / balanced seals to EN 12756 (DIN 24960)

Single and double cartridge seals with seal support system

2-Deepgroove ball bearings or double row angular contact thrust bearing and cylindrical roller bearing

Robust shaft design

Dry-shaft design, pumped liquid not in contact with the shaft

Less expensive than API pumps

| Part Name | Material |

|---|---|

| Casing | Cast iron FG260 / Cast Iron FG 200 / CF8 / CF8M / 2%NICI / Duplex Steel |

| Impeller | SS 304 / SS 316/Duplex Steel |

| Stuffing Box | Cast iron FG260 / Cast Iron FG 200 / CF8 / CF8M / 2%NICI / Duplex Steel |

| Pump Shaft | EN8 /SS 410 / SS 304 / SS 316/Duplex Steel |

| Shaft Sleeve | SS 410 /SS 304 / SS 316/Duplex Steel |

| Bearing bed | Cast iron |

| Gland | MS / SS |

Gland rope

Single Mechanical seal

Double Mechanical seal

Cartridge Seal

Base plate

Coupling (Love jaw/tyre/spacer/pin push)

Coupling guard

Foundation Bolt